| Pre-Manufacturing Approval As per clients requirements and specifications, General Arrangement drawing with foundation details, single line diagram and wiring drawing are submitted for approval before manufacturing of each of the products. The drawing are prepared keeping in mind of national and international standards related to switch gears and panels with the help of latest AutoCAD software and a skilled operator. |

| Fabrication We have a fabrication facility which is equipped with a 60 ton capacity Hydraulic Shearing machine for uniform cutting and a100 ton capacity Hydraulic press Brake machine for also equipped with other machines for Grinding, Drilling, Corner cutting and Welding. We strictly follow the standard of metal enclosed switchgear considering degree of protections as per IS 375, IS 2174 & IS 3427. The skilled machine operator and trained fabricator works day and night to achieve the production targets. |

| Surface Treatment We have 7/9 - Tanks process as per IS 6005. The Tank sizes are 2600 (L) x 2600 (W) x 1250 (D) mm. All the chemicals are duly controlled for its chemical properties at our test lab to achieve the best of the surface treatment on sheet metal parts. Due to this treatment the Phosphate layer is developed on sheet metal of panel which not only prevents the panel against corrosion but also results in a superior finished product. |

| Painting & Powder Coating We have spray painting facility as well as in house Powder Coating facility with oven size 2600 (H) x 2900 (D) x 1780 (L) mm to meet larger sections of panels. We provide Powder Coated panels are having longer life even in corrosive environment of industries. The best of the outlook is achieved through powder coating. |

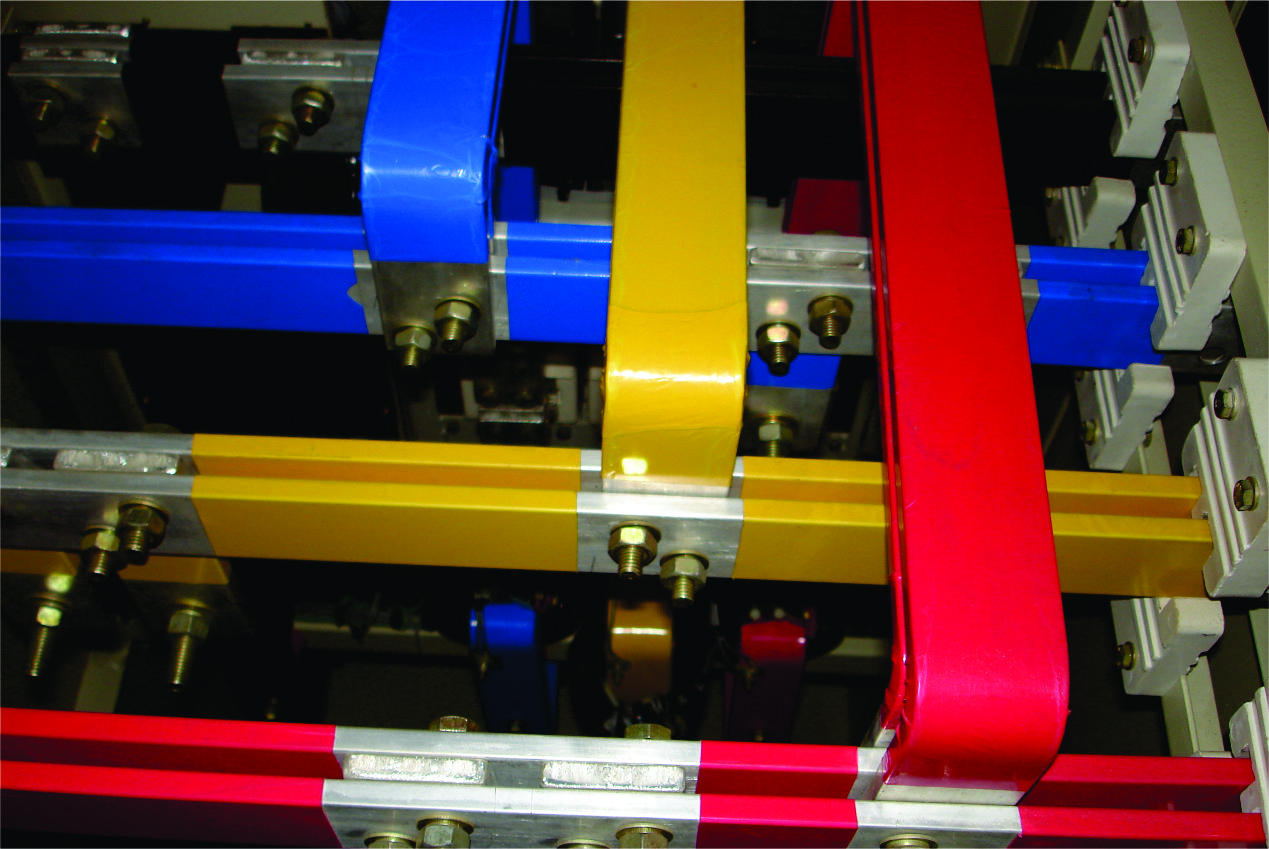

| Busbar Bending & Assembly Our panels are completely assembled and wired as per latest standards of IS 375 & IS 5578 considering all major safety aspects like busbar sleeving, busbar supports, safety shutters, earthing and door locking arrangement. The horizontal busbar, vertical busbar and incoming links are totally sleeved with heat shrink PVC which ensures protection against accidents due to tracking caused by dust, humidity and vermin. |

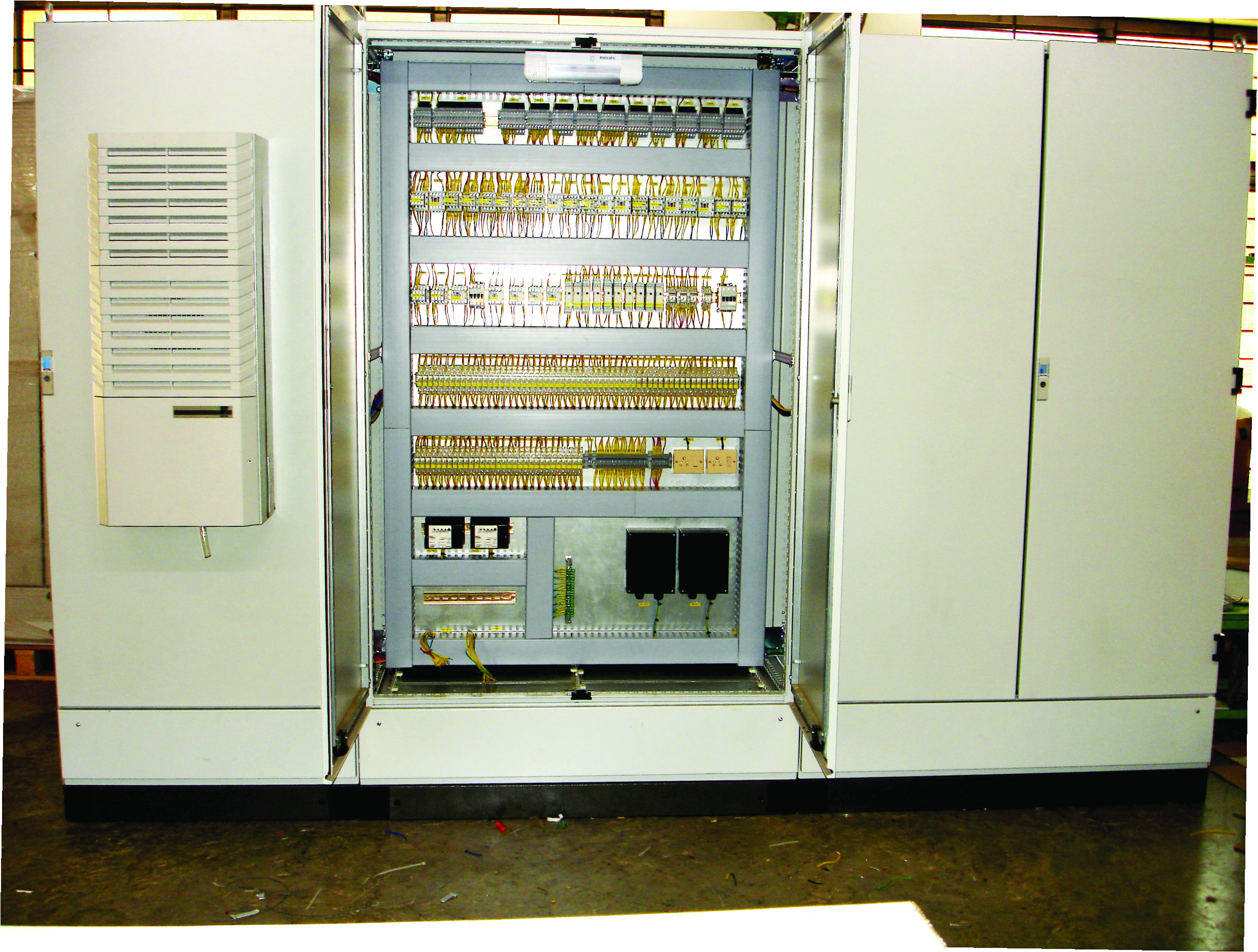

| Wiring Power and Control wiring is carried out as per scheme as well as selecting proper size of wire as per requirement. Rigorous in - house quality checks during wiring are imposed to achieve perfect traceability and identification. Extensive care is taken for labeling, gasketing and ferruling. The cross ferruling on the long lasting thermal sleeve is a code of practice for panel wiring with the help of latest printers. |

| Testing Even though all panels are manufactured in accordance with Indian Standards, they are thoroughly checked for routine tests, operation test, megger test using calibrated test before dispatch. Panels are Type of Tested CPRI Bhopal for: 1. Degree Of Protection IP 55 2. Short Circuit Withstand test 65 KA for 1 Second 3. Short Circuit Withstand test 50 KA for 1 Second |